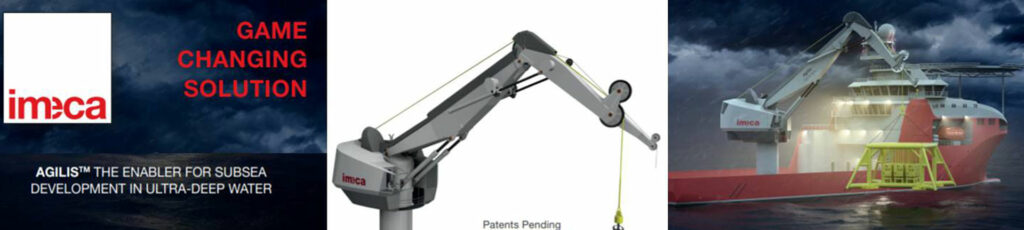

The enabler for placing the SWL in air @ “unlimited” water depth with incredible energy efficiency

The Imeca AgilisTM offers unique features that directly address the call cost reduction from operators while providing contractors and vessel owners with a means to distinguish themselves.

| UPTIME – Robust and maintenance-friendly design – Electric drive system with limited moving parts – Protected against environmental exposure – Condition-based maintenance – Remote support through Imeca Connect | EFFICIENCY – SWL @ (unlimited) depth – Optimized work area – System accuracy better than hydraulic – Small operating radius due to jib cylinder point – Small tail swing – Low weight & COG – Fully self-contained | GREEN DESIGN Low energy consumption & small CO2 footprint : – Electric drive system – Electric system with Peak Shaving capabilities – Regenerated power back to vessel grid (optional) – Storage medium for regenerated energy (optional) Minimal use of hydraulics |

| SAFETY – Fully enclosed access – Fiber rope monitoring & conditioning system – Overload Protection System | WORKABILITY – Superior heave compensation performance – Outstanding performance in harsh environments and low temperatures – No ice accumulation; smooth surfaces (heating optional) |

Based on many years of experience and proven track record of our offshore cranes team, we have designed the AgilisTM in such way that it can be easily retrofitted onto a new-build design or retrofitted to existing vessels instantly increasing efficiency.

Two elements were high on the agenda when developing this piece of equipment :

The AgilisTM subsea cranes feature Imeca’s patented fiber rope handling system.

Since fiber rope is neutral buoyant in water the length of the rope in water does not affect the lifting capacity, allowing large subsea lifts from relatively small vessels.

In addition the low weight and COG of the AgilisTM help to reduce the required vessel size even further.

To make the AgilisTM the most energy efficient subsea crane in the market the crane has electric winches and slewing motors.

This reduces the energy consumption with 30% compared to electric-hydraulic drive systems.

In addition Imecas patent pending peak-shaving solution optimizes power demand.

Due to this tremendous power efficiency it becomes very interesting to make use of the generated power when lowering a load to depth.

Optionally AgilisTM can be outfitted with an energy storage solution enabling AgilisTM to become a net producer of energy instead of a consumer.

|

AGILISTM |

||||||||||

| 50 | 60 | 70 | 80 | 100 | 120 | 150 | 200 | 250 | ||

| SWL, Double Fall (DF), Optional |

t |

80 | 100 | 110 | 125 | 160 | 190 | 240 | 300 | 400 |

| SWL, Single Fall (SF) |

t |

50 | 60 | 70 | 80 | 100 | 120 | 150 | 200 | 250 |

| Radius @ max SWL, (SF) |

m |

10 | 12 | 13 | 14 | 15 | 15 | 15 | 18 | 18 |

| Radius max Aux Hoist |

m |

30 | 30 | 32 | 32 | 34 | 35 | 36 | 40 | 40 |

| Hook travel |

m |

“UNLIMITED” |

||||||||

| Slewing |

deg |

FULLY REVOLVING |

||||||||

| Hoisting Speed @ Full SWL | m/min |

30 |

||||||||

| Hoisting Speed @ Reduced SWL | m/min |

120 |

||||||||

Your offshore crane with IMECA

REEL wishes you a happy new year 2023!

Groupe REEL takes over CNIM Systèmes Industriels, which designs and produces large-scale complex mechanical systems.

REEL becomes the first company in the world certified by DNV according to ISO 19443!

REEL and its teams wish you a Happy New Year 2022!